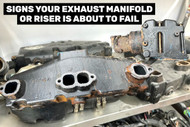

Signs Your Exhaust Manifold or Riser Is About to Fail

14th Feb 2026

An exhaust manifold or riser is failing when corrosion, internal wear, or cracking allows exhaust gases or cooling water to escape where they should not. Left unchecked, this can lead to overheating, water ingestion, and severe engine damage.

These components are critical to your marine exhaust system. The exhaust manifold collects hot gases from the engine, while the riser cools and elevates those gases before they exit the boat. Because they constantly deal with heat, saltwater, and pressure, they are among the most failure-prone parts on inboard and sterndrive engines.

Recognising the warning signs early can prevent breakdowns, protect your engine, and save thousands in repairs.

Unusual Exhaust Noise or Smell

One of the first signs of a failing exhaust manifold or riser is a change in sound. If your engine suddenly sounds louder, harsher, or uneven, exhaust gases may be escaping through a crack or weakened gasket. You may also notice exhaust fumes inside the engine bay or cockpit, which indicates the system is no longer sealed correctly.

This is not just unpleasant. Escaping exhaust gases can damage surrounding components and pose safety risks if fumes enter enclosed areas.

Visible Rust, Flaking, or Water Leaks

External corrosion is often a visible indicator of internal failure. Rust streaks, flaking metal, or damp areas around the manifold or riser joints usually mean the internal water passages are breaking down.

Once corrosion penetrates the internal walls, cooling water can leak into the exhaust path or engine bay. At this stage, replacement is usually the safest option rather than repair.

Many boat owners choose high-quality aftermarket exhaust components such as BARR and H2O, which are specifically designed to handle harsh marine environments and provide long-term corrosion resistance when matched correctly to the engine.

Engine Overheating or Temperature Fluctuations

A compromised exhaust manifold or riser can disrupt proper cooling water flow. When cooling efficiency drops, engine temperatures may rise unexpectedly or fluctuate during operation.

If your engine runs hotter than normal without an obvious cause such as a blocked strainer or failed impeller, the exhaust system should be inspected immediately. Overheating linked to exhaust issues is often progressive and becomes more severe with continued use.

Excessive Vibration or Rough Running

Internal blockages caused by corrosion or collapsed material can restrict exhaust flow. This often shows up as vibration, reduced performance, or rough running under load.

Engines rely on smooth exhaust gas evacuation. Any restriction increases back pressure, which directly affects efficiency, fuel burn, and long-term engine health.

Water Dripping Where It Should Not

Cooling water should exit with exhaust gases at the stern. Water appearing around the manifold, riser, or exhaust hose connections while the engine is running is a serious warning sign.

Even minor leaks indicate internal deterioration. At this point, continuing to run the engine significantly increases the risk of water reaching the cylinders.

Risk of Water Ingestion and Engine Damage

The most serious consequence of exhaust manifold or riser failure is water entering the engine. This can occur when internal corrosion allows cooling water to flow backward into the exhaust ports, particularly at idle or shutdown.

Water ingestion can cause hydrolock, bent connecting rods, damaged valves, and complete engine failure. In many cases, the damage occurs suddenly and without warning.

According to BoatUS, exhaust manifolds and risers are among the most commonly overlooked maintenance items despite being a leading cause of catastrophic engine damage.

How Long Do Exhaust Manifolds and Risers Last?

In saltwater environments, cast iron manifolds and risers often show significant internal corrosion within five to seven years, sometimes sooner, depending on usage and maintenance. Freshwater engines may last longer, but age alone is not a reliable indicator of condition.

For many popular inboard and sterndrive engines, quality aftermarket options from brands like BARR and H2O offer a proven balance of durability, performance, and value when replacement is required.

Boaters World stocks a wide range of exhaust manifolds and risers to suit common marine engines across Australia.

Frequently Asked Questions

What does an exhaust manifold do on a boat engine?

The exhaust manifold collects exhaust gases from the engine cylinders and directs them toward the riser while managing heat through internal cooling passages.

What is the purpose of an exhaust riser?

The riser cools exhaust gases further and raises them above the waterline to prevent seawater from flowing back into the engine.

How do I know if my riser is leaking internally?

Common signs include unexplained engine overheating, rust flakes in the exhaust, water dripping near exhaust joints, or corrosion visible during removal.

Are aftermarket exhaust manifolds reliable?

High-quality aftermarket brands such as BARR and H2O are widely used in marine applications and are designed to meet or exceed OEM performance when installed correctly.

Can a bad exhaust manifold damage my engine?

Yes. A failing manifold or riser can allow water into the engine, leading to hydrolock and severe internal damage.

Should manifolds and risers be replaced together?

In many cases, yes. Replacing both at the same time ensures proper sealing, balanced wear, and long-term reliability.

Is stainless steel better than cast iron?

Stainless steel offers improved corrosion resistance but must be correctly matched to the engine and exhaust design. Material choice depends on application and budget.

Can I inspect my exhaust manifold myself?

Visual inspection is possible, but internal corrosion is often hidden. Professional inspection or scheduled replacement is the safest approach.

What engines are most affected by riser failure?

Inboard and sterndrive engines using water-cooled exhaust systems are most at risk, especially those operating in saltwater.

How often should exhaust manifolds be checked?

They should be inspected annually and closely monitored once they reach mid-life expectancy.

Browse Now

If your engine shows any of these warning signs, do not wait for failure. Exhaust system issues escalate quickly, and repairs become far more expensive once water reaches the engine.

Browse Boaters World’s range of exhaust manifolds and risers, including trusted aftermarket options from BARR and H2O, and protect your engine before serious damage occurs.

Australian Dollars

Australian Dollars